Building a Test Stand | Half Scale Pinball

Projects:

On my way to a playable machine

These past months, I’ve been working to get the lower-third of the machine in a playable state so I can finally playtest. Thankfully, I’m nearly done as all I have left is the redesign of the flipper mech. The only problem is I didn’t have a way of propping the playfield at the correct angle or holding its sidewalls in place.

With full size machines, the playfield dimensions are at least somewhat standardized so you can borrow a cabinet from another machine or build your own from plans online but I’m not making a standard playfield. I do intend to build a cabinet for my machine but my playfield dimensions could still change so I don’t want to waste the time or money on the cabinet. Instead, I wanted to build something adjustable.

Aluminum extrusion FTW

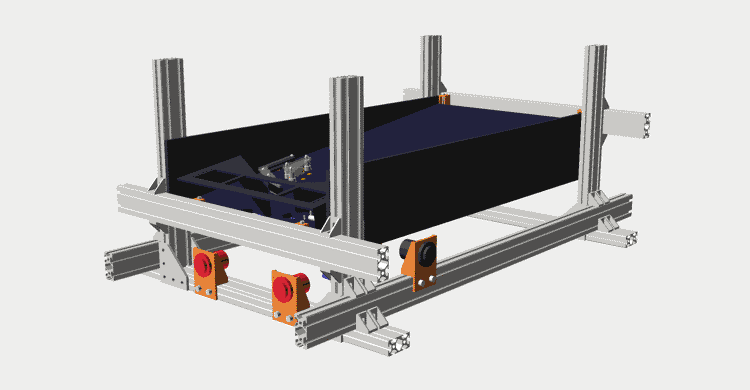

I figured my best option was to build the test stand from aluminum extrusion. It’s relatively cheap, available precut, and reusable. I spent a few days in CAD and came up with this design.

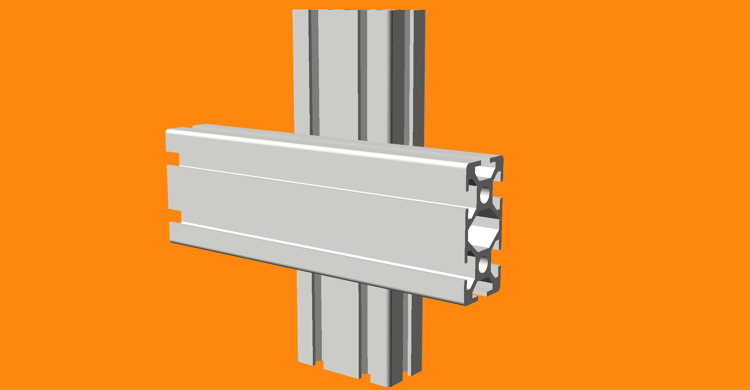

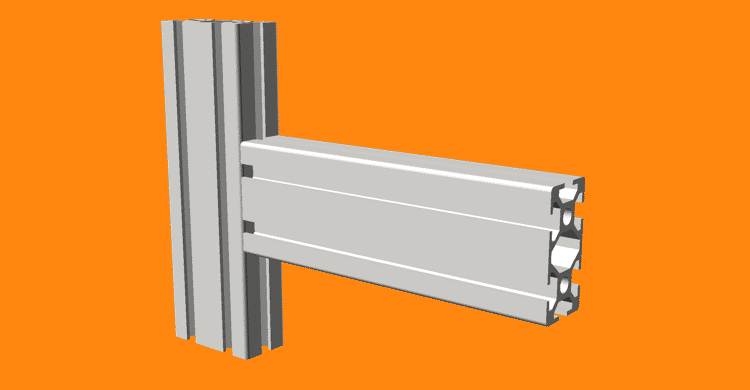

This isn't how you'd normally join extrusions but doing it this way lets each side slide in/out to fit the playfield

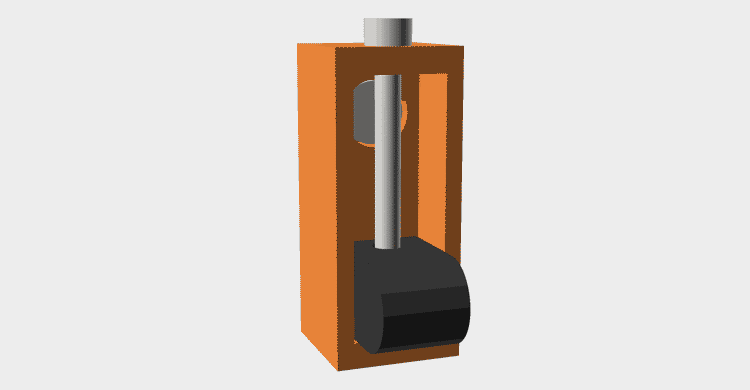

Now, extrusion isn’t a precision component. The beams can be warped and bowed (they are after all the product of forcing molten aluminum through a die). Thing is, even if the extrusions were perfect, there’s no guarantee my table or floor are. To compensate for that, the playfield is resting on four adjustable carriages for levelling.

Each playfield support consists of an M3 bolt as a lead screw and a carriage with heatset insert that engages with it

Assembly

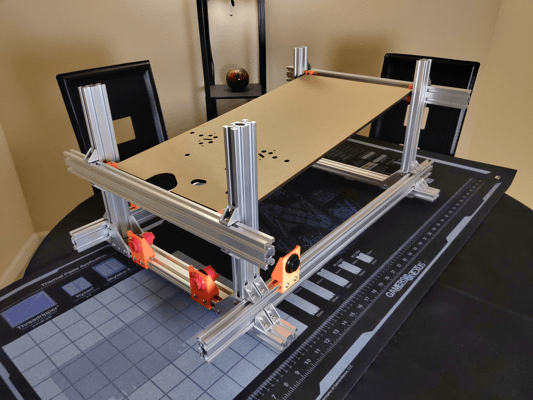

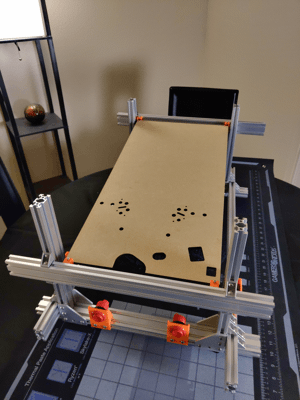

One hour and 96 bolts later and I have the stand assembled

Assembly went smoothly for the most part but there was one unforeseen problem. For the extrusions supporting the playfield, there are plenty of plates and brackets designed to join extrusions whose channels are parallel but I couldn’t find anything meant to join extrusions with perpendicular channels. What do I mean? Well take a look at these renders.

This is how I want to join my extrusions

Now, you wouldn’t normally join extrusions like this; however, joining them the normal way would require cutting them to exact sizes and defeat the purpose of the stand. Joining them this way allows for excess extrusion so I can slide the joints closer/further apart to accomidate the playfield.

But this is how extrusions are intended to be joined

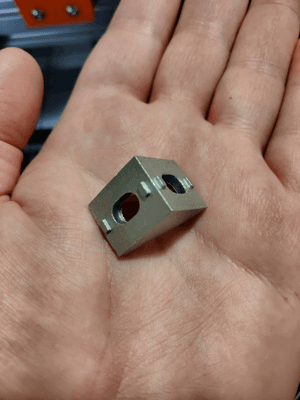

But wait, what about those little corner brackets in the picture? Well, there in lies the problem. You see, those brackets actually have little tabs on bottom meant to align them with the channel. Unfortunately, those tabs are spaced too far apart to fit in the channel sideways so for one of the perpendicular extrusions it’s not actually making contact with the flat part of the bracket.

Note how the tabs are thin enough to fit in the channel one way but are too far apart to fit the other way

While this does affect how precise the joint angles are, that isn’t really the biggest problem here. What I soon discovered was these tabs dig into the sides of the extrusion and effectively lock it in place even when you loosen the bolts. This makes it much more fiddly to adjust the dimensions of the stand than I had intended.

I’ve since thought of a few other ways I could have constructed the stand to avoid this but it’s good enough for now that I’m fine with it as is. Also note, I did find some different brackets that don’t have the alignment tabs; although, they may not work for this application since they are designed to attach from the ends not the channels.

If you get nothing else from this post, just take this as a word of caution in case you plan on building something out of aluminum extrusion as well. Hackaday has a great article on how to properly join and constrain extrusions if you’re interested.

Playfield

You may have already noticed the fancy new lasercut playfield. It’s a bit barren and this is far from a final layout (I don’t even know yet if I’ll be using the standard “Italian” design) but it will at least let me mount all the mechs I’ve designed for testing.

The lasercut playfield fits nicely in the new stand